- info@tekiskalip.com.tr

- TOSB 1.Cadde 14.Sokak No:5 Çayırova / Kocaeli

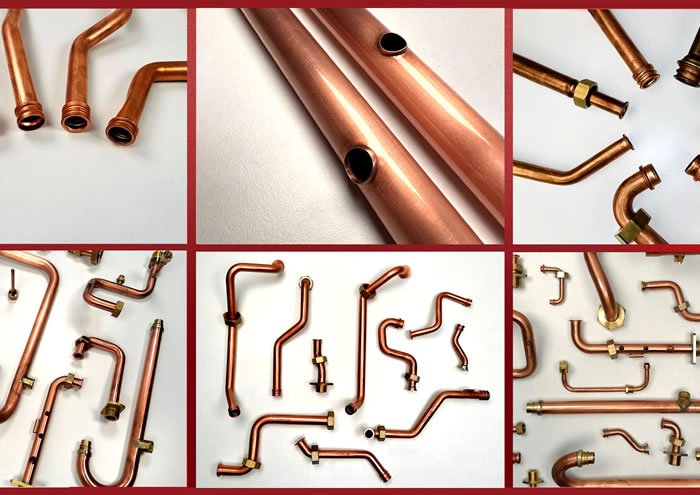

Precision Copper Tube Forming: Engineered Excellence with Tekiș Kalıp

Precision Copper Tube Forming: Engineered Excellence with Tekiș Kalıp

Delivering reliability and performance where precision matters most

Why Copper Tube Forming Demands Precision Engineering

In high-performance industries like HVAC, appliances, automotive, and medical systems, copper tubing is the backbone of thermal and fluid transport. Its unique combination of conductivity, corrosion resistance, and formability makes it the preferred material—but only when it’s shaped precisely, without compromising structural or functional integrity.

At Tekiș Kalıp, copper tube forming isn’t just a process—it’s a controlled engineering operation that leverages 20+ years of manufacturing experience, advanced CNC capabilities, and a deep understanding of copper metallurgy.

What Is Copper Tube Forming?

Copper tube forming includes a series of specialized operations applied to copper tubes ranging from 6 mm to 50 mm in diameter, such as:

- Precision bending to exact radii

- End-forming (expanding, reducing, flaring)

- Cutting and hole piercing

- Bell forming, threading, or swaging

- Flange pressing or specialty shapes

Despite copper’s softness, uncontrolled processing can lead to deformation, cracking, or dimensional instability. This is why forming copper correctly demands advanced tooling, tightly monitored forces, and specialized dies.

Tekiș Kalıp’s Approach to Copper Tube Forming

At Tekiș Kalıp, we take a materials-first engineering approach. Every process is designed to preserve the core properties of copper—its thermal conductivity, dimensional stability, and unobstructed internal flow —while meeting exacting client specifications.

CNC Tube Bending

- Programmable angles and tight bend radii

- Minimal ovality and wrinkling

- Ideal for HVAC and white goods applications

Tube End-Forming

- Expansion and reduction

- Bell forming for leak-proof connections

- Threading (internal and external)

- Custom forms for specialty fittings

Precision Cutting and Drilling

- Burr-free, chipless cutting

- CNC hole punching for manifold assemblies

- High-speed automation for serial production

Custom Dies & Prototyping

- Rapid die design for special connectors

- One-off and low-volume prototype manufacturing

- Close collaboration with your engineering and R&D departments

Maintaining the Integrity of Copper’s Natural Advantages

Copper’s performance comes from its structure. Degrading that structure during manufacturing risks thermal inefficiency, leakage, or component failure. That’s why we apply best practices in copper handling:

- Controlled process temperatures

- Special die coatings to reduce friction

- Lubrication protocols to minimize work hardening

- Protective film or inline cleaning when required

Our parts maintain shape, strength, and cleanliness, ensuring full functional performance both in the lab and in the field.

Industries Served with Formed Copper Tubes

Tekiș Kalıp forms copper tubes for global OEMs and Tier 1 suppliers across:

- HVAC – A/C systems, boilers, chillers, heat pumps

- Appliances – Refrigerators, freezers, dishwashers

- Medical Equipment – Liquid and gas transfer lines

- Automotive – Fuel lines, cooling systems, brake tubing

Built on Technology, Driven by Quality

Every operation at Tekiș Kalıp is backed by a quality-first mindset:

- CAD/CAM-assisted tool design

- CNC-driven forming and cutting

- In-line inspection with digital measurement tools

- ISO 9001-certified production environment

- 100% final part verification upon request

We go beyond forming— we optimize and engineer the entire lifecycle - from design to delivery.

Why Choose Tekiș Kalıp for Copper Tube Forming?

- Specialized knowledge in copper behavior

- Project-specific engineering support

- Precision machinery and tooling

- Commitment to consistent, repeatable quality

Our mission is to deliver durable, efficient, and tailored solutions that meet the performance expectations of demanding industries.

Let’s Shape the Future of Copper Tube Performance—Together

If your project requires precision-formed copper tubing, let Tekiș Kalıp be your trusted partner in manufacturing. From HVAC to high-tech medical systems, we shape copper to exacting standards—so your products perform with confidence.