- info@tekiskalip.com.tr

- TOSB 1.Cadde 14.Sokak No:5 Çayırova / Kocaeli

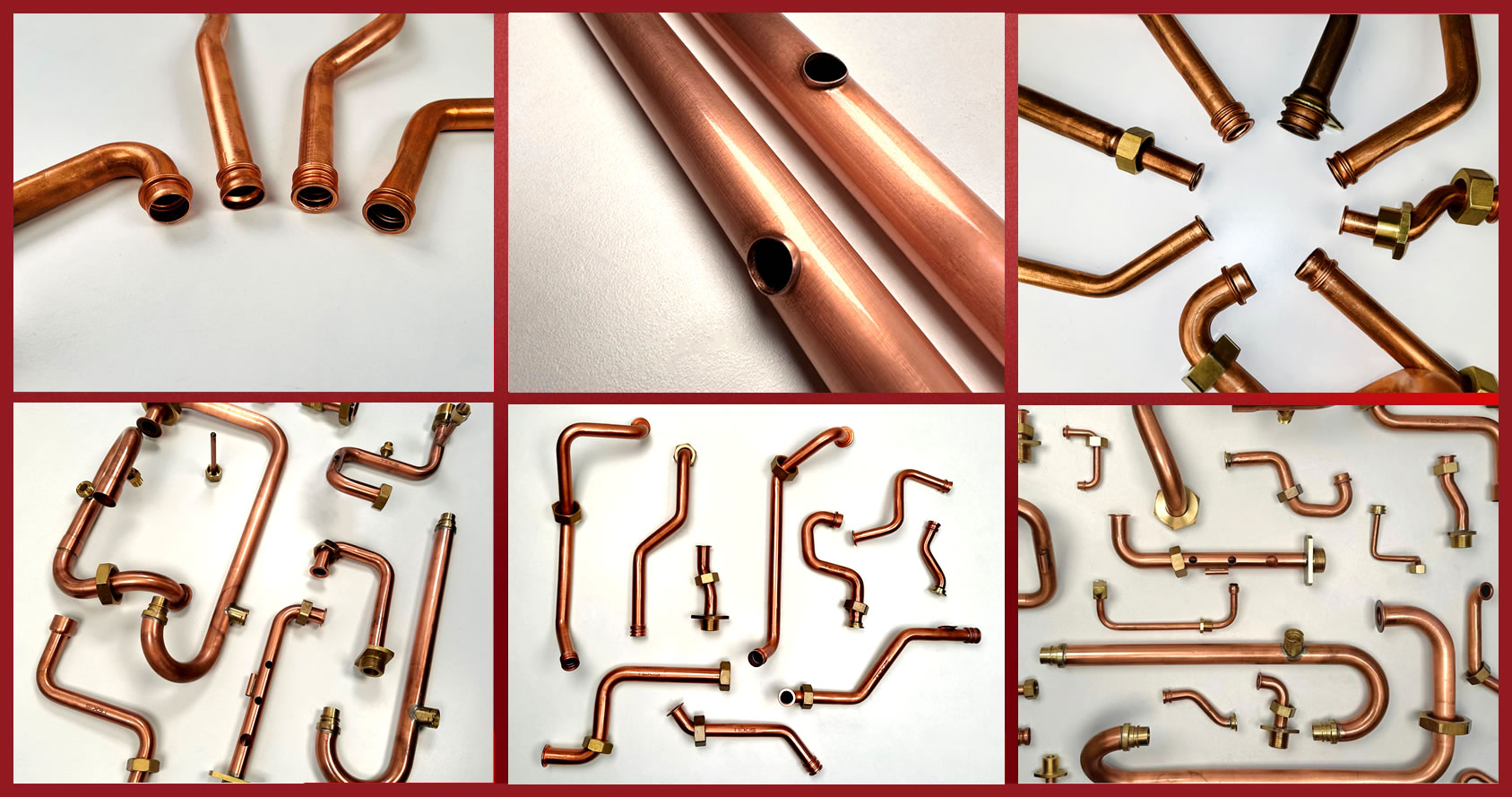

Tube Bending & End Forming Solutions

Advanced Tube Forming Solutions for Boiler & Heat Pump Applications

- Capable of Bending: Cr, Al, and Copper alloy tubes with precision.

- High Production Capacity: Up to 300 tonnes per year, meeting large-scale demands.

- Versatile Tube Sizes: Supports tube diameters from 4 mm to 28 mm and lengths up to 1 meter.

- 7 + 1 Axis Bending: Ensures complex bends with high precision and flexibility.

- Wide Bending Angles: Capable of bending up to 160° for customized shapes.

- Prototype & Pilot Production: Tailored solutions for early-stage product development.

- In-House 3D Design Tools: Custom-designed bending tools for maximum accuracy and efficiency.

Precision Tooling Solutions for Tube Bending & End Forming

Custom Tooling & Rapid Production for Perfect Tube Shaping

- Rapid Production: Custom tooling designed and manufactured within just 2 weeks.

- 3D CAD Design: Advanced 3D CAD modeling for precise and efficient tooling development.

- CNC Precision Manufacturing: High-accuracy CNC machining for consistent and reliable tooling production.

- Versatile Tooling: Compatible with tube diameters from 4 mm to 28 mm.

- Tailored Solutions: Engineered for both tube bending and end forming, meeting your exact specifications.

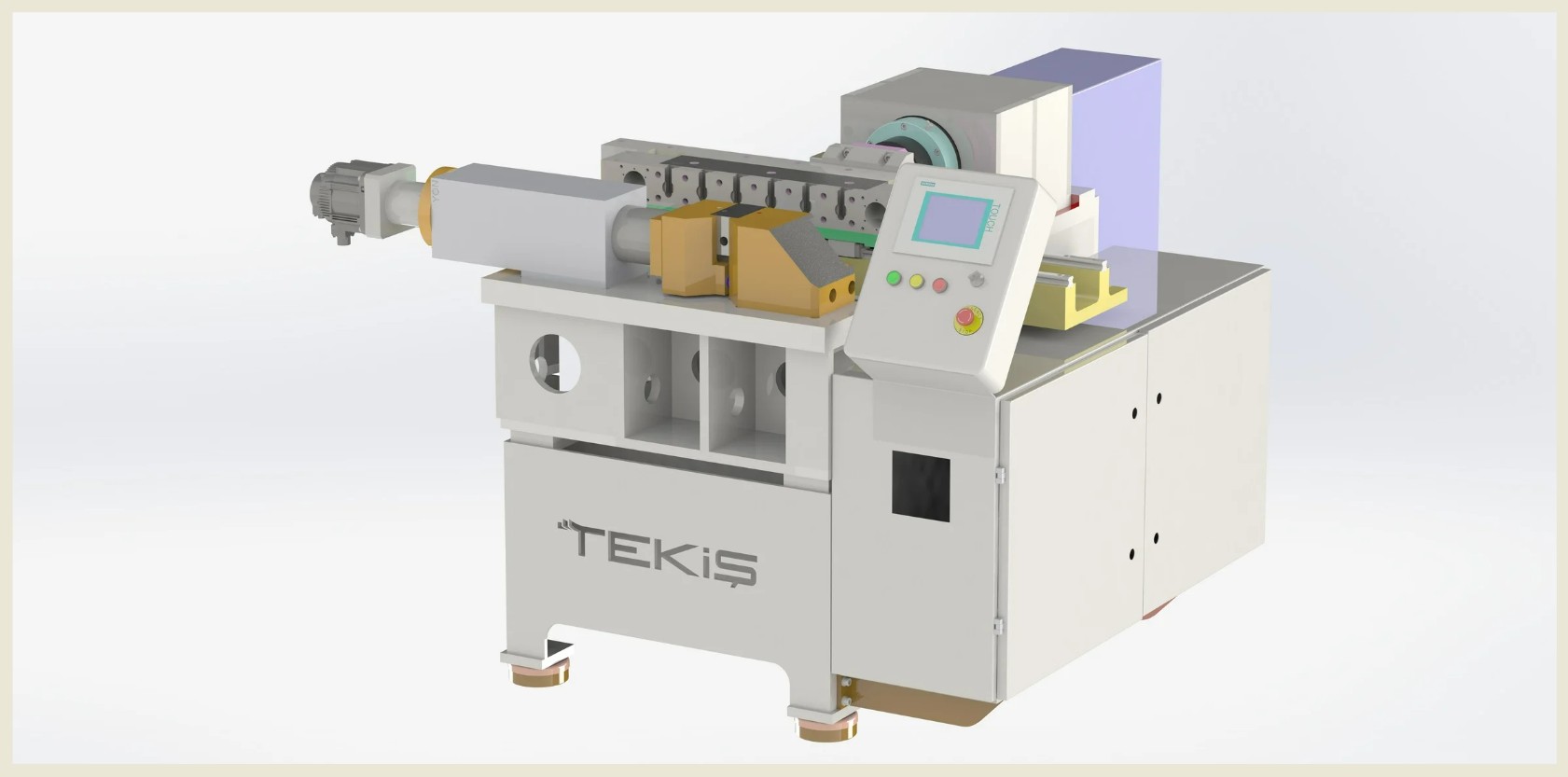

8-Station Tube End Forming Machine

Precision Tube End Forming with Advanced Technology for Maximum Efficiency

- PLC Numeric Control: Advanced control system ensuring precision and consistency.

- 8-Station Setup: Multi-station design for increased productivity and efficiency.

- 350 Nm Torque Servo Motors: High-performance motors delivering smooth and powerful operation.

- High Throughput: Produces up to 360 pieces per hour, maximizing production capacity.

- Unmatched Precision: ±0.05 mm axis accuracy for flawless tube end forming.